Food – Unsupported

Trayless product solutions keep things moving.

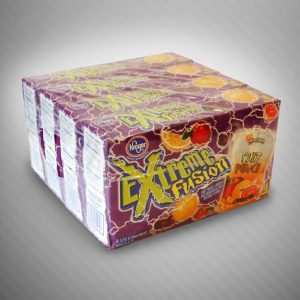

Automatically accumulate, collate, and wrap products in a bulls eye wrap

Unsupported Food Products

- Products with rigid primary packing; cans, cartons, cases, etc.

- Products with material strength capable of accommodating pallet loading flour, sugar, rice, dry beans, etc.

Cost Savings

- Remove corrugate cost (case or tray)

- Remove adhesive or tape cost

Flight Bar Automatic

Reduce film use, consume less energy and shrink bundle products with ease. Bundle and shrink wrap a wide variety of supported or unsupported products with this flexible solution.

EDL’s Flight Bar Automatic shrink wrapping machine provides the best combination of product handling and throughput rates. Common applications include light weight products or small multi-packs which require substantial handling throughout the wrapping process.

Automatic Flight Bar with Side Seal and Forming Shoe: Plastic Medical Bottles (SV145) (video)

Inline Automatic Shrink Wrap Machine

Maximize your speed and efficiency, while maintaining package quality. Experience an Inline Automatic Shrink Wrap Machine.

Inline Automatic Shrink Wrap machines are EDL’s most flexible secondary packaging solution. These systems are designed to shrink-wrap a variety of products, including bundling and shrink-wrapping cartons to shrink-wrapping large windows in multiple package enclosures at low to moderate speeds.

What’s the Difference Between Inline Automatic and Continuous Motion Systems?

Integrated Ancillary Equipment

Solving systems integration challenges.

EDL can provide total systems integration for our customers looking for a turn-key solution. EDL’s complete system engineering responsibility includes start to finish integration of systems from conveyors to palletizers and everything in between.

What Exactly is Ancillary Packaging Equipment?

Semi-Automatic Wrapper

Semi-Automatic Wrapper handles trayed, tray less or padded products. When high quality packs are required but full automation is secondary.

The Semi-Automatic Wrapper (Monobloc Semi-Automatic) is a cost-efficient, secondary or end-of-line packaging solution for a wide range of applications. It is designed for reduced throughput rates and requires operator loading of product and activation of each wrapping sequence. This versatile system can be quickly and easily integrated into existing production lines.

Side Feed Automatic

The versatile Side Feed Automatic shrink wrapping equipment is easily integrated into your existing production line. Turn, tier or invert collated products during infeed for correct orientation prior to wrapping.

EDL’s Side-Feed Automatic shrink wrapping equipment is designed to handle a wide variety of applications while providing a small footprint and flexible layout designs. This type of system is ideal for products that require collating or enter the system with the narrow edge leading. Multiple package enclosures are available.

Single Roll Wrapper

Fast, efficient throughput: Single Roll Wrappers offer the highest throughput for trayed and trayless applications.

EDL’s single roll wrapping systems offer our highest throughput rates typically from 20 -45 packs per minute. Common applications include trays of food or beverage product and collations of containers. The single roll wrapping system is based on an inline layout and can be easily integrated into an EDL up stream wrap around tray former. EDL single roll wrappers can run clear and print registered film.

Single Tight Wrapper

Single Tight Wrap Bundling gives you a tighter, better-looking package. Single Tight Wrap utilizes EDL’s tight wrap technology to provide a superior wrapped product.

EDL’s single tight wrap bundling machine uses Tight Wrap technology to reduce film and energy consumption. Single Tight Wrap can replace traditional shrink bundling systems in certain applications and can also be an alternative to strapping, gluing and PVC shrink sleeves.

Shrink Tunnel

Heavy-duty, reliable and tailored to your product and package

Shrink tunnels are essential for achieving secure and professional packaging using shrink film. The heat applied in these tunnels causes the shrink film to tightly conform to product contours, ensuring long-lasting protection during transportation, storage, and display.

Our shrink tunnels, also known as heated shrink tunnels or shrink wrap tunnels, feature a high temperature-rated Habasit conveyor belt and a dual-shell hood design with ceramic fiber insulation for efficient heat retention. They include a direct drive overhead hot air blower and silicone entrance and exit curtains for precise heat distribution. Film cooling fans at the exit ensure a smooth finish.

- High temperature rated Habasit conveyor belt

- Dual shell tunnel hood design

- Ceramic fiber insulation between exterior and interior hood shells

- Ceramic fiber mat insulation between hood assembly and tunnel frame

- Direct drive overhead hot air recirculation blower

- Silicone tunnel entrance and exit curtains

- Film cooling fans at exit

Contact us to learn more about the shrink tunnel machine.