Building Materials

From fence posts to ceiling tiles.

We have you covered.

EDL has a wide range of shrink wrap packaging machine options and configurations tailored to the building supply industry.

- Seal Jaws ranging from 12″ to 144″ for the largest size capacity in the industry.

- Automated film carriage option for size flexibility without changeover.

- Side trim options for improve pack aesthetics.

Cost-savings, flexibility and performance all rolled into one. EDL has been providing fast, tough and reliable end-of-line packaging systems to the flooring industry for more than 25 years.

- Rugged machine construction for 24/7 packaging operations.

- Flexibility to handle a variety of products with little or no change over.

- Innovative ways to increase throughput.

- High efficiency shrink tunnel for reduction in energy usage.

Three Products That Can Benefit from Shrink Bundling and Wrapping

Forming Shoe Wrapper

Protect your product, keep its integrity, and withstand shipping and handling. For unique applications where speed and efficiency are the top priority.

EDL’s Forming Shoe packaging machine utilizes a unique wrapping technique that produces a totally enclosed pack. Product, typically a stacked, nested or tightly wound material, is driven through a shoe where film is fed around it until it is totally enclosed. Forming shoe systems can incorporate a shrink tunnel depending on the application.

Inline Automatic Shrink Wrap Machine

Maximize your speed and efficiency, while maintaining package quality. Experience an Inline Automatic Shrink Wrap Machine.

Inline Automatic Shrink Wrap machines are EDL’s most flexible secondary packaging solution. These systems are designed to shrink-wrap a variety of products, including bundling and shrink-wrapping cartons to shrink-wrapping large windows in multiple package enclosures at low to moderate speeds.

What’s the Difference Between Inline Automatic and Continuous Motion Systems?

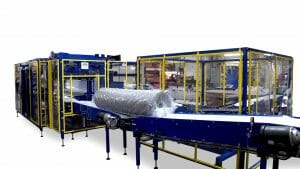

Integrated Ancillary Equipment

Solving systems integration challenges.

EDL can provide total systems integration for our customers looking for a turn-key solution. EDL’s complete system engineering responsibility includes start to finish integration of systems from conveyors to palletizers and everything in between.

What Exactly is Ancillary Packaging Equipment?

Roll Wrapper

Package and protect your rolled products.

Roll Wrapping solutions for carpet, vinyl flooring, fabric, textiles, rubber, felt, and more. EDL’s roll wrapping machines are designed to wrap rolled products. Common applications include carpeting, foam padding, textiles and rolled building materials. The side feed layout of the roll wrapper allows for easy integration of additional modules for further system capabilities.

Shrink Tunnel

Heavy-duty, reliable and tailored to your product and package

Shrink tunnels are essential for achieving secure and professional packaging using shrink film. The heat applied in these tunnels causes the shrink film to tightly conform to product contours, ensuring long-lasting protection during transportation, storage, and display.

Our shrink tunnels, also known as heated shrink tunnels or shrink wrap tunnels, feature a high temperature-rated Habasit conveyor belt and a dual-shell hood design with ceramic fiber insulation for efficient heat retention. They include a direct drive overhead hot air blower and silicone entrance and exit curtains for precise heat distribution. Film cooling fans at the exit ensure a smooth finish.

- High temperature rated Habasit conveyor belt

- Dual shell tunnel hood design

- Ceramic fiber insulation between exterior and interior hood shells

- Ceramic fiber mat insulation between hood assembly and tunnel frame

- Direct drive overhead hot air recirculation blower

- Silicone tunnel entrance and exit curtains

- Film cooling fans at exit

Contact us to learn more about the shrink tunnel machine.

The EDL Packaging Engineers Guarantee

- Performance Guarantee ensures EDL machines will perform as specified. All machines are thoroughly tested to the highest standards

- Equipment Warranty provides a full two-year warranty on parts (equipment warranty excludes consumables)

Flexibility. Performance. Quality. End-of-line packaging equipment for the flooring industry all rolled into one.

EDL Packaging understands that the flooring industry is comprised of various products and materials, each with a different set of material handling and packaging requirements, that’s why we don’t offer a one-size-fits-all solution. Instead, EDL works with customers to develop a wrapping system based on their packaging needs and goals.

25 Years’ of wrapping experience meets the flooring industry

EDL has manufactured several wrapping systems designed to bag, fully-enclose, or hold together carpet padding and rugs. In addition, EDL parent company, Massman Automation, manufactures cartoning solutions for carpet tiles and planks.

Case Study: What the Building Product Industry Can Learn From Window and Door Manufacturers