Pet Food/Petcare

Pet food packaging solutions that generate loyalty.

EDL has experience manufacturing tailored secondary and end-of-line packaging machines for the pet food industry.

- Pet food packaging solutions enable our customer to revolutionize filling, sealing, bundling, palletizing, placing and wrapping pet food products.

- EDL will partner with customers and bring together the industry’s preferred suppliers in one turn-key system while assuming total engineering responsibility!

- EDL builds rugged and reliable systems that run with 98% efficiency, 24 hours per day, 7 days per week, while lowering energy, film and productions costs.

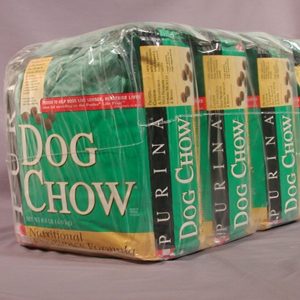

- EDL’s signature Double Tight Wrap technology pulls gable top bags tightly together with low density polyethylene film to produce consistent brick like packs that can be palletized without pallet overhang.

Double Tight Wrap

Double Tight Wrap Shrink Wrapping Machines: Get unitization, stability, protection, and product visibility.

EDL’s Double Tight Wrap Shrink Wrapping machine is the packaging industry’s gold standard in tight wrap technology.

EDL Double Tight Wrap shrink wrapping machines use two perpendicular bands of LDPE film to tightly unitize and totally enclose a product or collation. Common applications include gable-topped bagged and pouch products and cube-shaped products requiring total enclosure. Markets have benefited include pet food, food service consumables, and food.

Integrated Ancillary Equipment

Solving systems integration challenges.

EDL can provide total systems integration for our customers looking for a turn-key solution. EDL’s complete system engineering responsibility includes start to finish integration of systems from conveyors to palletizers and everything in between.

What Exactly is Ancillary Packaging Equipment?

Semi-Automatic Wrapper

Semi-Automatic Wrapper handles trayed, tray less or padded products. When high quality packs are required but full automation is secondary.

The Semi-Automatic Wrapper (Monobloc Semi-Automatic) is a cost-efficient, secondary or end-of-line packaging solution for a wide range of applications. It is designed for reduced throughput rates and requires operator loading of product and activation of each wrapping sequence. This versatile system can be quickly and easily integrated into existing production lines.

Shrink Tunnel

Heavy-duty, reliable and tailored to your product and package

Shrink tunnels are essential for achieving secure and professional packaging using shrink film. The heat applied in these tunnels causes the shrink film to tightly conform to product contours, ensuring long-lasting protection during transportation, storage, and display.

Our shrink tunnels, also known as heated shrink tunnels or shrink wrap tunnels, feature a high temperature-rated Habasit conveyor belt and a dual-shell hood design with ceramic fiber insulation for efficient heat retention. They include a direct drive overhead hot air blower and silicone entrance and exit curtains for precise heat distribution. Film cooling fans at the exit ensure a smooth finish.

- High temperature rated Habasit conveyor belt

- Dual shell tunnel hood design

- Ceramic fiber insulation between exterior and interior hood shells

- Ceramic fiber mat insulation between hood assembly and tunnel frame

- Direct drive overhead hot air recirculation blower

- Silicone tunnel entrance and exit curtains

- Film cooling fans at exit

Contact us to learn more about the shrink tunnel machine.

The EDL Packaging Engineers Guarantee

- Performance Guarantee ensures EDL machines will perform as specified. All machines are thoroughly tested to the highest standards

- Equipment Warranty provides a full two-year warranty on parts (equipment warranty excludes consumables)